Extraction test

Determining the ground conditions and load-bearing capacity is an essential step in the planning and realisation of photovoltaic projects. Various methods and techniques are used to ensure that the subsoil fulfils the requirements and that the safety of the construction is guaranteed. The most important methods include pull-out tests, which help to determine the load-bearing capacity of the ground. Pull-out tests also allow conclusions to be drawn about the duration and pressure setting on the hydraulic pile drivers. Finally, a pull-out test also provides information about the topography and valuable information for assessing the subsoil.

Determining the load-bearing capacity of the floor

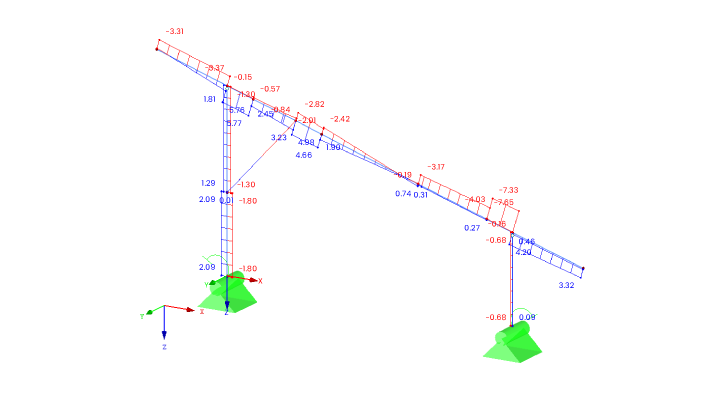

The tests to determine the bearing capacity of the soil are based on empirical methods that provide direct and precise measurements. These methods allow detailed data to be collected on the physical properties of the soil, including its strength, compactability and behaviour under load. This empirical data is invaluable as it provides a realistic assessment of the soil's bearing capacity that goes far beyond theoretical calculations.

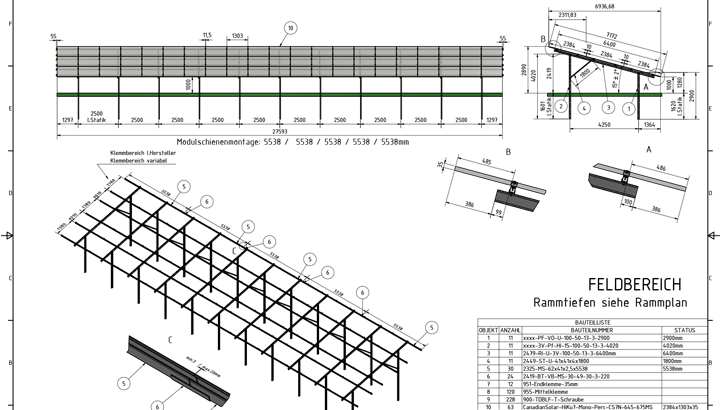

Thanks to the precise measurements and analyses, the foundations of the structure can be dimensioned in an extremely practical way. This means that the size, shape and depth of the foundations can be optimally adapted to the specific conditions of the subsoil. Such customised dimensioning ensures that the foundations transfer the system's loads efficiently and safely into the ground, guaranteeing the stability and longevity of the entire structure.

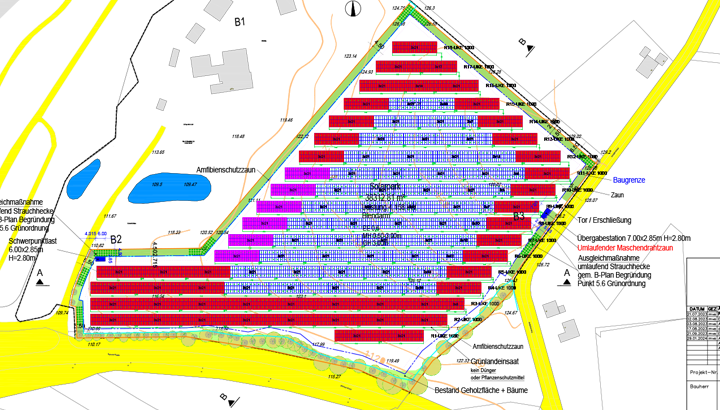

Another advantage of empirically determining soil properties is that it enables engineers to recognise potential problems at an early stage and take appropriate measures. For example, weak points in the soil, such as areas with lower load-bearing capacity or increased water content, can be identified and taken into account. These weak points can be compensated for by making targeted adjustments to the foundation design, such as reinforcements or additional drainage measures.

In addition, the precise dimensioning of the foundations ensures that the substructures of the building are highly stable. This is particularly important in areas with variable ground conditions or in seismically active regions, where the loads on the foundations can be particularly high. Careful planning and dimensioning ensures that the foundations can withstand the forces that occur and safely support the structure.

Pile-driving capability and pressure settings

In addition to the basic determination of the bearing capacity and cohesion of the soil, a pull-out test also provides crucial information on the specific requirements and adjustments that may be necessary when using hydraulic pile drivers.

The pull-out tests allow our experts to collect detailed data that is used to fine-tune the duration and pressure settings of the hydraulic pile drivers. The test data provides information on how the soil reacts to the application of pressure and how much force is required to achieve a certain penetration depth. This information is essential to adjust the hydraulic rams so that they work efficiently and safely without causing excessive stress or damage to the device and the soil.

Especially in very hard or very stony terrain, the knowledge gained from the pull-out tests is essential. These conditions often require special measures, such as pre-drilling. The pull-out test can show whether the soil is so resistant that direct ramming could be ineffective or even harmful.

Topography and basic observations

The personal execution of pull-out tests by our experts not only provides precise and reliable data on the soil conditions, but also has another extremely positive side effect: during the tests, the experts can simultaneously gather important findings and observations that are of great importance for the subsequent assembly of the structure.

By interacting directly with the ground and observing the conditions on site, our experts can identify potential challenges and optimisation opportunities for delivery and installation at an early stage. For example, they can recognise whether special machines or tools are required to bring the materials safely and efficiently to the installation site. They can also identify potential obstacles such as uneven terrain, narrow access roads or soft ground that require special attention or preparation.