Root system

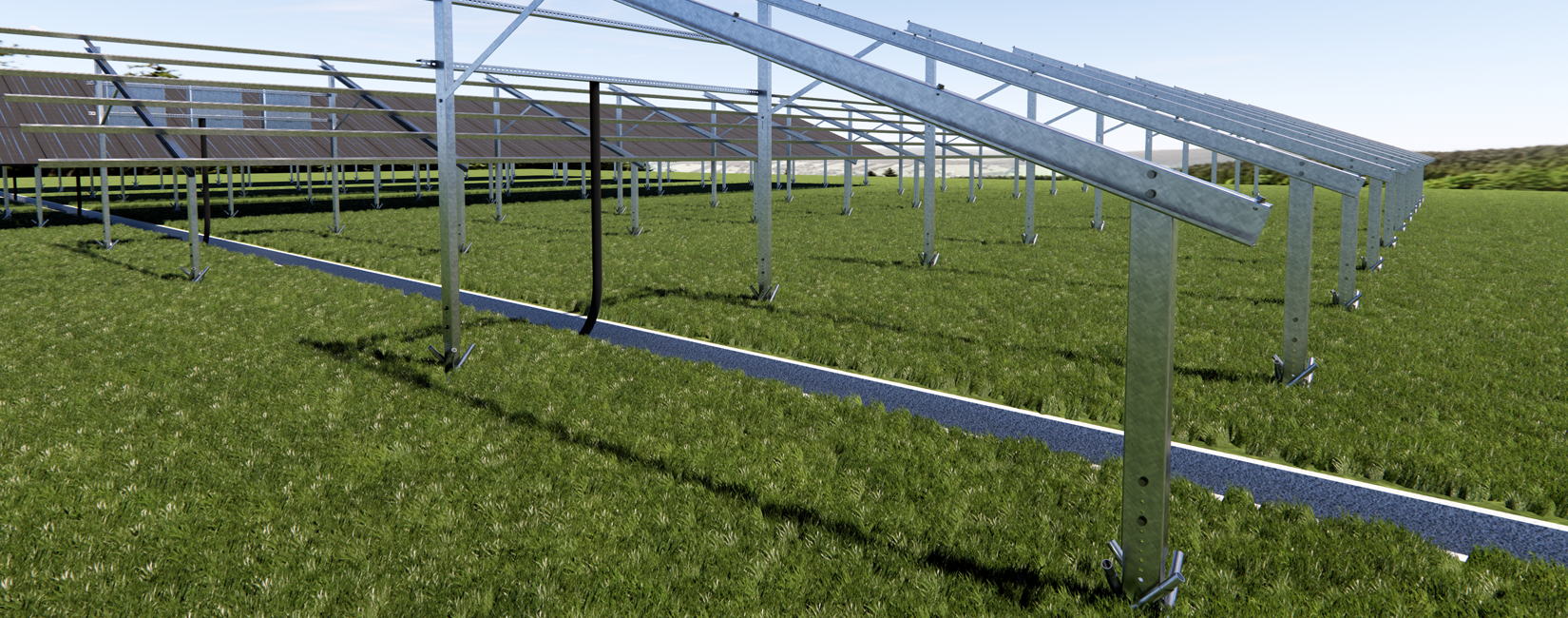

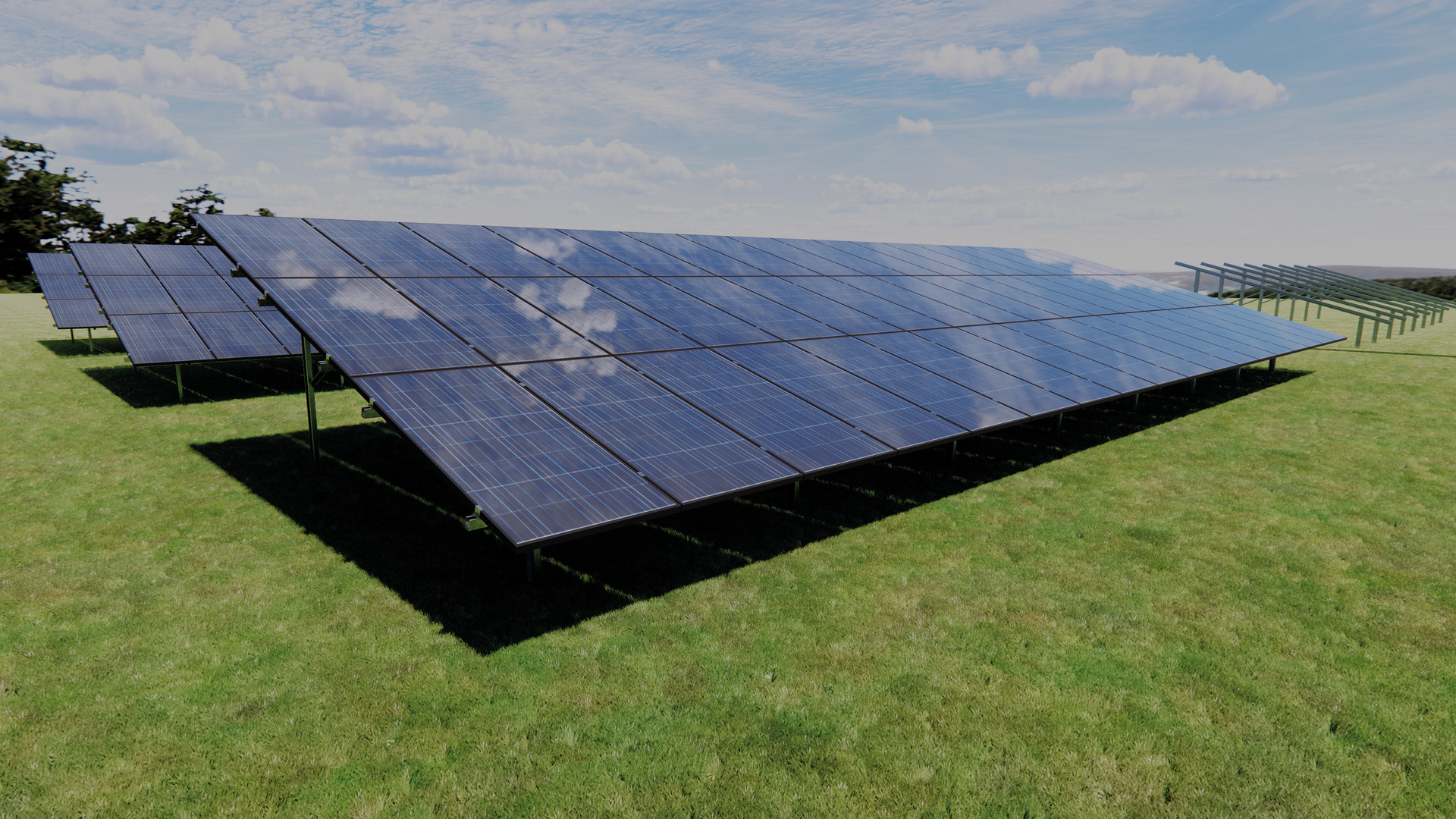

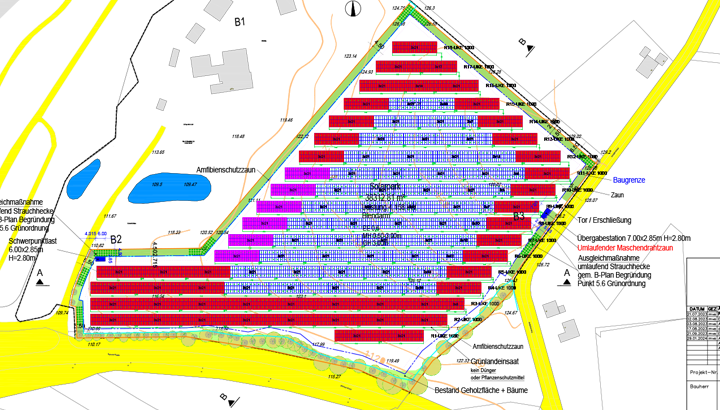

This technology enables the safe and stable installation of photovoltaic systems even in challenging terrain conditions that cannot be covered by conventional driven piles. The root system is characterised by its low penetration depth and extreme stability, which makes it ideal for use on steep terrain, soft ground, landfills, conversion areas, sites with ground monuments and the smallest ground-mounted PV systems.

The limits of conventional driven piles

The average pile-driving depth for conventional piles is approx. 1.6-2.0 metres.

This depth is often a problem, particularly in the case of landfills, sites with ground monuments, stony plots and conversion areas with underground obstacles such as concrete and wall remains:

- Sealed landfills usually have a sealing film at a depth of approx. 80 cm, which is intended to safely drain off any gases that arise. This film must not be penetrated and the permitted pile-driving depth is reduced to a range of only 70 cm. This automatically rules out the use of conventional piling posts.

- Stony soils usually solidify and compact with increasing depth. In many cases, a closed rock slab is reached after less than one metre. Driving in normal piles is impossible here without cost-intensive pre-drilling.

- Groundwater conditions: The soil survey(s) also takes into account the groundwater conditions, which can influence the stability and longevity of the foundations.

- Conversion areas such as former barracks, industrial sites or railway facilities often have a long history and have often been built on with various buildings over the course of decades of use. These buildings were usually demolished to a depth of approx. 1.0 metre below ground level. Remaining foundations, pipes and sewers were then usually simply pushed in. Here too, it is impossible for the supports to penetrate to a depth of 1.6 metres.

Negative aspects of conventional pile driving

Conventional posts are driven using hydraulic rams with chain drive. They usually have a dead weight of more than 4.0 tonnes and are suitable for work on terrain with a slope of no more than 20°. This results in various disadvantages:

- High costs for transport to and from the site by low-loader.

- High rents.

- Specialised machine operators required.

- Slopes, embankments, hills and mountains with a gradient greater than 20° can no longer be built on.

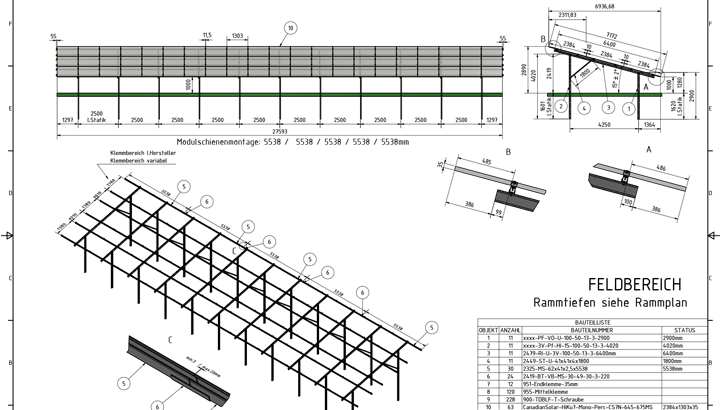

Simple installation of the root system

The installation of our root system is comparatively uncomplicated and can even be carried out using a standard impact drill. This ease of installation not only reduces installation costs, but also allows it to be used in remote or difficult to access areas where the use of heavy pile drivers would not be possible or economical. The quick and easy installation helps to reduce overall project costs and speed up the commissioning of PV systems.

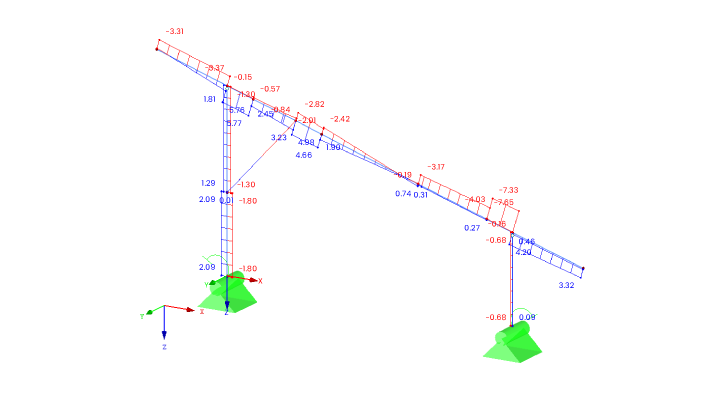

Extreme hold

The basic functional principle of foundations based on driven profiles is the friction between the ground and the surface of the profile. The vertical pull-out forces play a primary role here. The PV modules act like a sail that can be subjected to airflow from two sides. An inflow from the south ensures that the supports are pressed in (compressive load).

An inflow from the north causes the supports to be pulled out (suction load).

No risk of sinking

Dutch marshland, landscapes with boggy soils, very sandy ground or terrain with a very high moisture content, such as floodplains and flood plains, cannot be built on using conventional driven piles or concrete foundations (risk of subsidence).

Root systems offer a remedy here. The functional principle of "friction" is extended here by the angled guidance of the soil nails. These are not aligned directly in the effective direction of the support loads, but at an angle of approx. 45° to them. This allows additional soil to be activated and the load-bearing capacity to be significantly increased.

This function allows protection against both sinking in and pulling out and is realised with long soil nails on a project-specific basis.

Extreme corrosion protection

Saline marsh soils, contaminated conversion areas or soils with a high pH value ensure extremely rapid removal of the zinc coating on conventional driven piles. At the same time, project planners and general contractors are under high cost pressure. This means that countermeasures such as stainless steel supports or concrete foundations are often ruled out.

Our root systems provide a remedy here: only the relatively small soil nails and no other components are located in the ground. Form-Tec is therefore able to offer powder-coated or thick galvanised soil nails very cost-effectively and efficiently.

Are you planning to use the system for a a lifetime in critical ground conditions? No problem! In contrast to conventional driven posts, ground spikes can be replaced at any time and at low cost.

Completely removable

- At the end of the useful life of the PV system or if the area is to be used for other purposes, the root system can be completely removed.

- All components can be completely dismantled, allowing the floor to be restored to its original state.

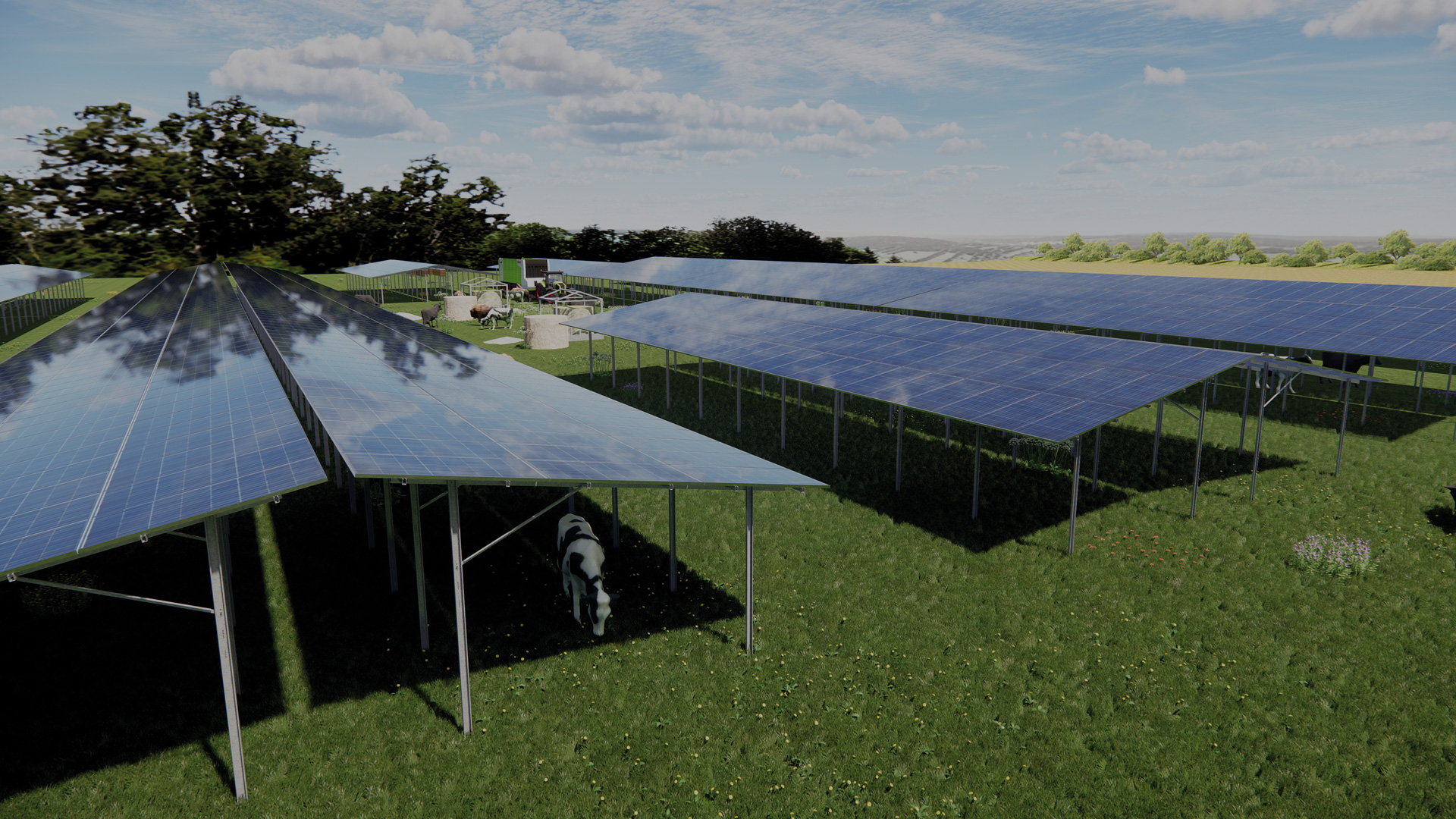

- Important for agricultural land that is to be made available for agricultural cultivation again after utilisation for energy generation.

Innovative & sustainable

Overall, our root system offers an innovative and sustainable solution for anchoring photovoltaic systems. The low penetration depth, the possibility of installation on slopes of up to 40°, the simple installation with an impact drill and the complete removability make this system an ideal choice for the utilisation of renewable energies on a wide variety of terrains and land use types. Thanks to these features, the root system makes a decisive contribution to the efficiency and environmental friendliness of PV systems on open spaces and agricultural land.

Do you have questions?

Give us a call. Or write us an email. We're here to help.

Joel Rempe

Contact

More than just profiles

- Customised solutions that meet the specific requirements of each project.

- Additional services such as technical advice, project management support, occupancy and pile-driving plans and much more.

- Focus on a holistic view of the projects to ensure that the products are perfectly harmonised.